The sustainable operation of the chemical industry relies on its workforce. Amid labour shortages, attracting talent for specialised and technical roles is crucial for both short-term functionality and long-term success. Safety is a critical factor for protecting the health of both employees and consumers, and the industry continuously strives to prevent accidents through a strong safety culture. When designing for sustainability, the industry focuses on employee and environmental safety during production, the safety of the production process itself, and the chemical safety of products. The chemical industry addresses the social targets of the UN-SDGs by improving safety, thereby supporting decent work (SDG 8) and good health (SDG 3).

Contribution to the EU Green Deal

The EU Green Deal prioritises improving the well-being and health of citizens and future generations. The chemical industry plays an important role in achieving these goals by driving innovation and sustainability, creating employment opportunities, and contributing to economic growth. By investing in future-proof jobs and skills training, the industry ensures its workforce is adaptable and skilled for the transition to a circular and digital economy. Additionally, the industry maintains stringent operational safety standards to protect workers and the environment, ensuring the overall well-being of employees and surrounding communities.

Employment

The workforce in the chemical industry is vital for its sustainable operation both in the short and long term. In times of labour shortages, attracting necessary talent for specialised and technical vacancies in the chemical sector becomes imperative.

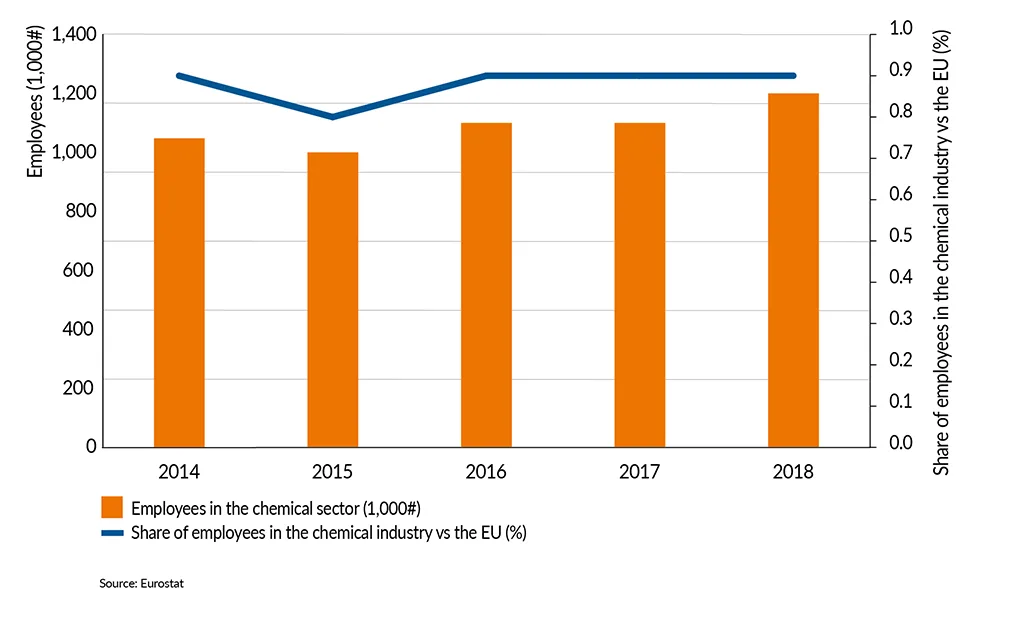

With slightly over 1.2 million employees, the chemical industry accounts for approximately 0.8% of all employees in the EU economy.

Employment in the EU27 chemical industry

Operational Safety

Safety is the key factor for the chemical industry to protect and maintain the health of both employees and consumers. The chemical industry strives continuously to prevent accidents by embedding a strong safety culture.

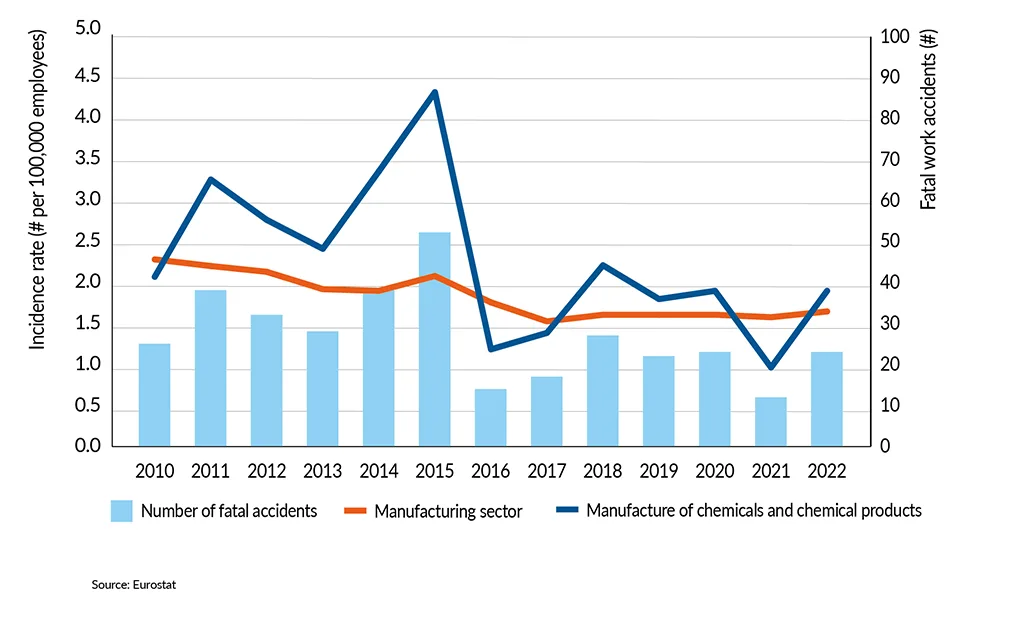

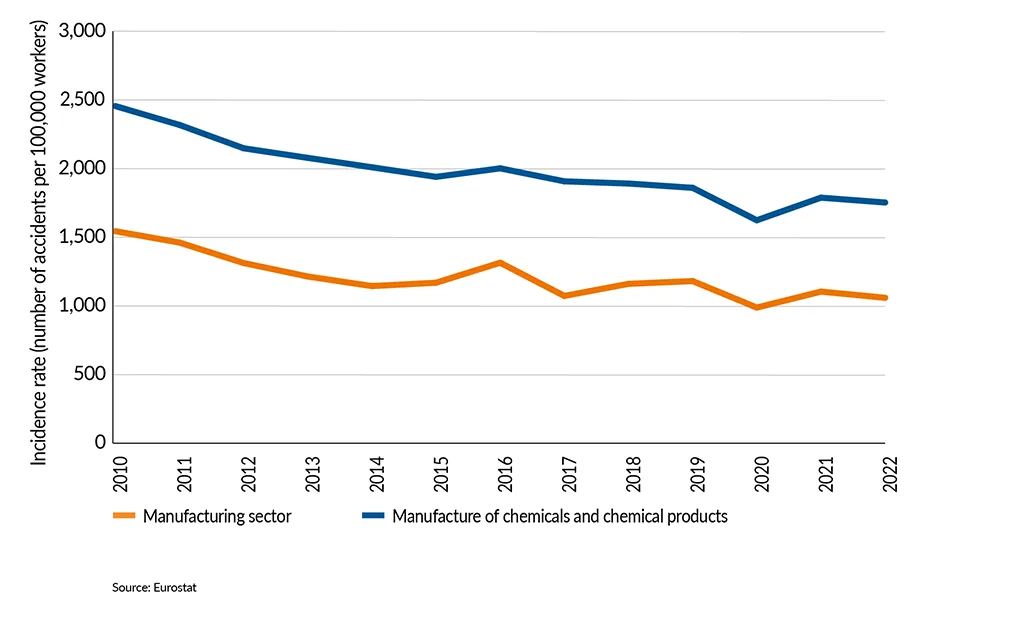

In 2021, the incidence rate of non-fatal accidents at work has decreased by 31% since 2010. The incident rate of fatal accidents has been fluctuating but remains very low. The sector continues to work on improving safety among its workforce, with accident prevention remaining a top priority.

Non-fatal accidents in the EU27 chemical industry

Fatal work accidents in the EU27 chemical industry