Solutions explained

Person of contact

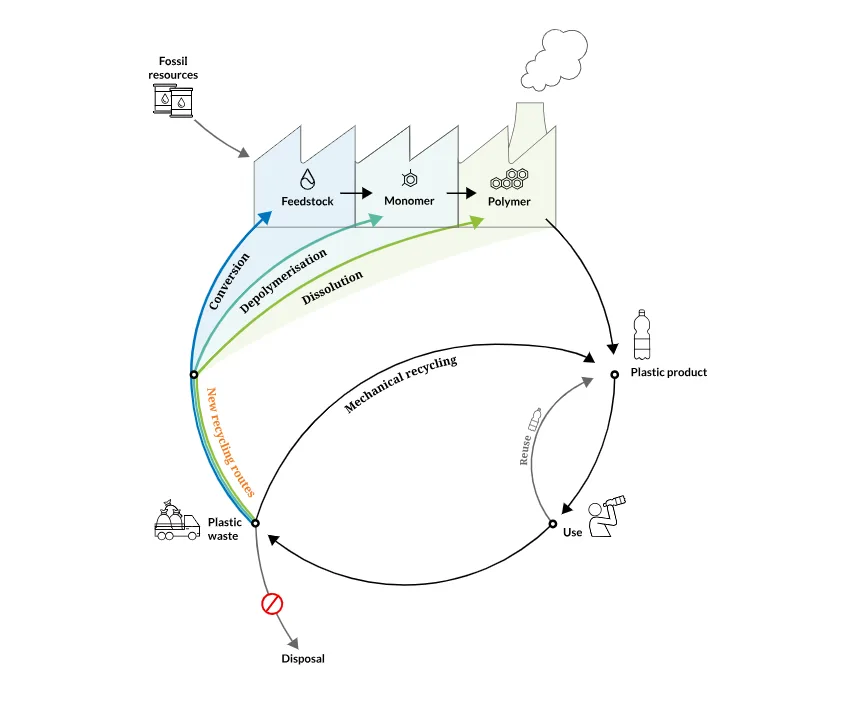

Achieving a circular economy for plastics

Around 30 million tonnes of plastic waste is collected in Europe every year, yet over 70% is incinerated, landfilled, or exported, leading to CO₂ emissions and loss of valuable resources (source). Over the past years, the chemical industry has been researching and investing in new technologies such as chemical recycling to offer a solution to the plastic waste challenge.

The European ambition to transition from a linear economy towards a sustainable circular economy calls for an array of complementary recycling options and business models. Chemical recycling can use end-of-life plastics waste streams to make new chemicals, including plastics, complementing mechanical recycling.

By implementing chemical recycling technologies at scale in Europe, the chemical industry can increase resource efficiency and help close the loop in the transition to a circular economy for plastics.

This shift will accelerate the shift from a ‘waste-orientated’ to a ‘resource-orientated’ economy, helping to create a true single market for secondary raw materials. It will make Europe less dependent on carbon imports, as carbon-rich waste streams can be used as a readily available resource.

Our chemical industry is determined to support Europe’s shift to a circular economy, and for several years has been calling for a supportive policy framework to deploy these technologies at scale. Read more about chemical recycling and check out examples from across the industry of chemical recycling projects.

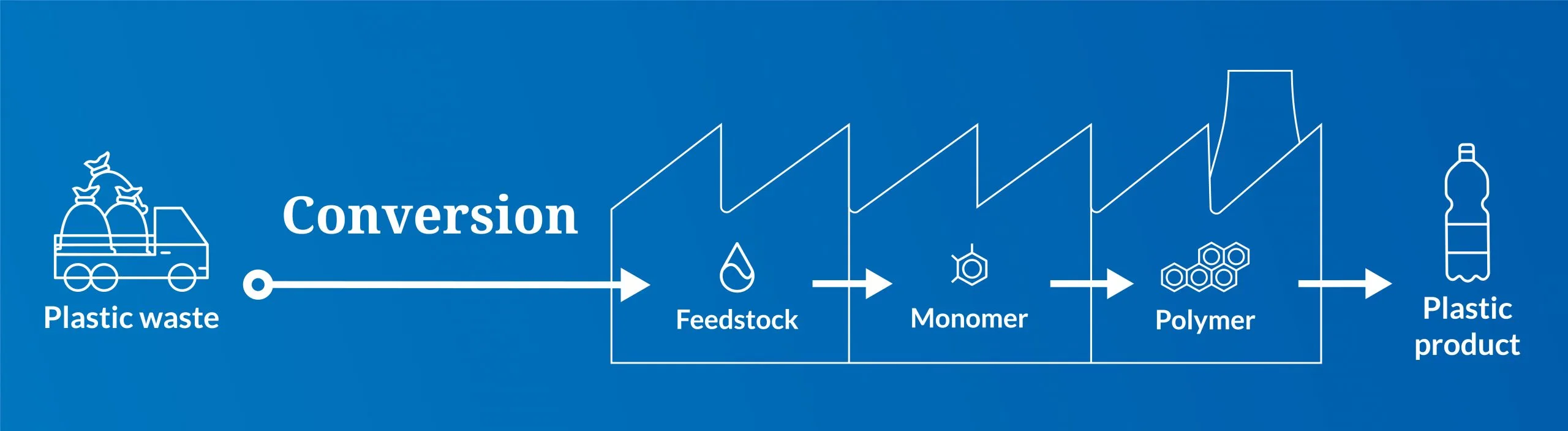

How do “new recycling routes” that complement mechanical recycling work?

Complementary recycling routes to mechanical recycling can enable even hard-to-recycle plastics to be repurposed.

- Mechanical recycling can process plastic waste into secondary raw materials or products without significantly altering their chemical structure.

- Chemical recycling routes like ‘depolymerisation’ and ‘conversion’ can transform plastic waste into secondary raw materials to be reintroduced at different steps of the plastic production process

Positive environmental footprint of chemical recycling

In 2023, as described in the report published by the European Commission’s Joint Research Centre “Environmental and economic assessment of plastic waste – A comparison of mechanical, physical, chemical recycling and energy recovery of plastic waste”, the preferred management option for plastic waste is recycling (mechanical, physical or chemical) from a climate change perspective and based on Life Cycle Assessments (LCA). Recycling (mechanical, physical or chemical) is preferable to energy recovery (incineration). As the European energy mix will get cleaner, the gap between recycling and energy recovery will further increase in favour of recycling, the study concludes.

Chemical recycling has an overall lower carbon footprint compared to today’s end-of-life practices of incineration and landfilling. As described in the 2020 Cefic-Quantis LCA report, chemical recycling (pyrolysis) of mixed plastic waste emits less CO2 than incineration of the same waste.

Other recycling route

Complementary to mechanical and chemical recycling, a new physical recycling route, called dissolution, has emerged. Physical recycling also known as dissolution dissolves plastic waste using solvents to extract the polymers and create new recycled plastic products. All recycling routes are fundamental to achieve a circular economy.

Discover the chemical recycling groundbreaking products and processes:

-

-

-

-

-

Case Study Design for Recycling – Textile Flooring

Case Study Design for Recycling – Textile Flooring -

Case Study Enhancing the quality of pyrolysis oil

Case Study Enhancing the quality of pyrolysis oil -

-

-

-

Case Study Taking PET recycling to the next level

Case Study Taking PET recycling to the next level -

Case Study Repsol Reciclex ® – Circular Resins

Case Study Repsol Reciclex ® – Circular Resins -