“NextLab” the sustainable detergent innovation: sustainability without sacrificing performance

Safe and Sustainable Chemicals, Spain

A leading initiative by Cepsa Química.

Cepsa Química is at the forefront of the transition to a circular economy in the homecare industry with its innovative NextLab products. NextLab offers similar outstanding properties as traditional Linear Alkylbenzene (LAB) but with significantly lower carbon emissions. It’s based on alternative feedstocks such as vegetable oils, waste, or end-of-life products. With NextLab, it becomes possible to formulate sustainable detergents that reduce the carbon footprint while maintaining high performance.

In the homecare industry, LAB is a crucial raw material, mainly used in biodegradable detergents. The total LAB market is substantial, estimated at 3.5 million metric tons, with projected growth to 4.1 million metric tons by 2030. The homecare sector consumes over 92% of this market.

Linear Alkylbenzene Sulfonate (LAS), derived from LAB, constitutes nearly 60% of the global primary surfactant demand in household products due to its exceptional properties. It is known for its excellent performance, ease of processing, and compatibility with other ingredients, making it a key component in various detergent products, including traditional powders, bars, capsules, and concentrated liquids.

As sustainability gains prominence in the homecare industry, consumers and stakeholders across the value chain increasingly prioritize more sustainable products. Achieving sustainability in detergent products requires alternative ingredients to replace those derived from fossil-based materials without compromising performance.

Cepsa Química operates in various industrial sectors, including engineering plastics, cosmetics, biodegradable detergents, paints, electronic components, pharmaceuticals, and more. The company is committed to developing pioneering chemicals that help clients create high-performing products while minimizing their environmental impact. Cepsa Química has embraced sustainable chemistry, and in the LAB business, it has introduced NextLab, a new product family aimed at transforming the industry and enabling customers to produce more sustainable detergents without compromising specifications and performance.

To address sustainability comprehensively and create the NextLab product family, Cepsa Química focuses on four key levers:

- Maximising Alternative Feedstocks: Cepsa Química uses renewable and circular materials derived from sources such as vegetable oils, waste, or end-of-life products (NextLab-R and NextLab-C).

- Low-Impact Production: The company optimizes processes and utilises renewable energy sources like biogas and renewable electricity instead of conventional fossil fuels to reduce direct and indirect emissions (NextLab-Low Carbon).

- Sustainability-Driven Innovation: Cepsa Química collaborates with customers to develop a sustainable product portfolio, with extensive testing and adaptation to meet modern detergent formulation challenges.

- Leadership and Collaboration: The company actively engages with customers, technology providers, and policymakers to shape sustainability discussions in its core business segments.

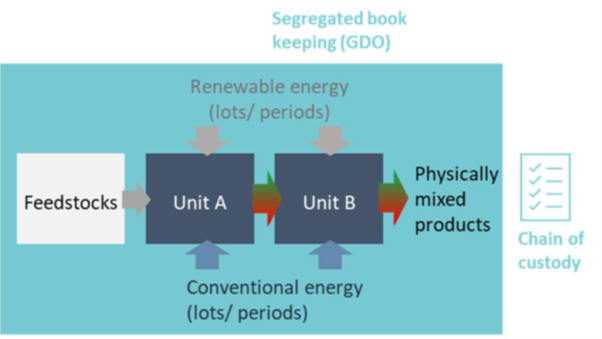

NextLab-R, the first LAB from sustainable sources, is an attractive solution for formulating sustainable detergents. It is manufactured using a mass balance approach, allowing the co-processing of fossil and sustainable raw materials while tracking them throughout the process. NextLab-R is available in two categories, NextLab-R68 and NextLab-R100, produced from 68% and 100% renewable raw materials, respectively.

NextLab-R68 has a significantly reduced carbon footprint compared to its fossil counterpart, with savings of up to 79%. These savings translate to lower greenhouse gas emissions in detergents formulated with NextLab-R68.

NextLab-Low Carbon, currently available in the NAFTA region, is produced using renewable energy sources, further reducing greenhouse gas emissions during production. It is produced in Bécancour’s Cepsa Química plant and offers similar reductions in carbon emissions when replacing fossil LAB.

By transitioning to NextLab products, the homecare industry can significantly improve the sustainability of detergents while maintaining technical performance. For example, detergent formulations using NextLab-R68 achieve substantial carbon savings.

Cepsa Química’s commitment to sustainability extends to the entire industry, with potential CO2 savings of up to 1,230,000 kg per year when considering the whole LAB market transitioning to NextLab-Low Carbon in 2030. For NextLab-R68, these savings are even higher, amounting to up to 5,412,000 kg of CO2 per year.

NextLab represents the beginning of an industrial transformation that offers a fresh perspective on sustainable solutions: sustainability without sacrificing performance. Cepsa Química’s innovative approach aligns with the growing demand for eco-friendly products in the homecare industry while contributing to a more sustainable future.