What goes around, comes around

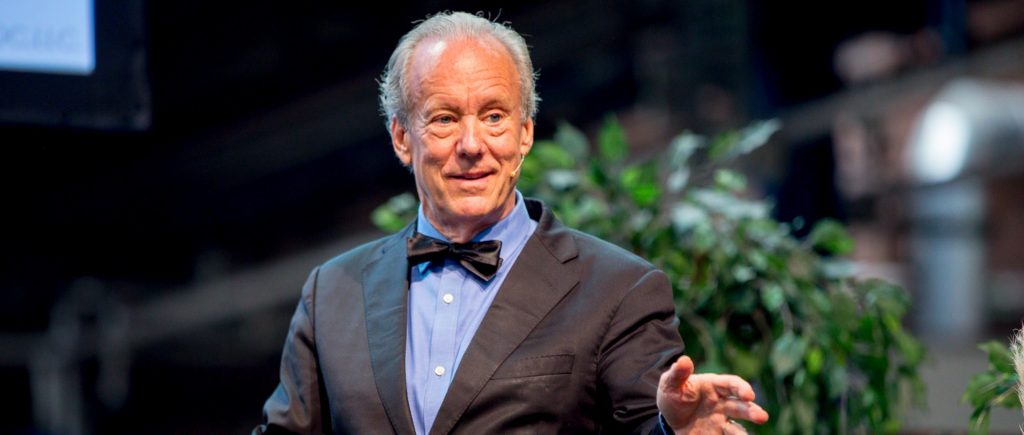

Architect William McDonough explains how far-sighted design can help create a circular economy

For decades, American architect William McDonough has been arguing for a circular economy, where products, and even buildings, are designed to be dismantled and reused when they’ve fulfilled their original purpose. Now a central pillar of the EU’s sustainability strategy, the idea has been a “40-year overnight success,” quips McDonough.

McDonough and German chemist Michael Braungart made a detailed case for the circular economy in a book they co-authored called Cradle to Cradle: Remaking The Way We Make Things, published in 2002. The book has since spawned the California-based Cradle to Cradle Products Innovation Institute that certifies products across five attributes – material health, circularity, renewable energy, water stewardship and social fairness.

Cradle to Cradle design aims to keep raw materials in the economy for longer, so less materials and energy are needed while producing more. It means creating a product, or even an entire building, that can be disassembled into identifiable materials and components for reuse in new products, either by the original manufacturer or by another company, which may even be willing to pay for the materials.

In addition to the clear environmental benefits, there are other drivers behind the circular economy. As the cost of raw materials rises, the business case for re-using resources is becoming stronger. The main point of Cradle to Cradle is that “our raw materials are still here,” McDonough explains. “To circulate [a material] again properly is like doubling the size of the economy, in terms of the material flowing through it, but you don’t have to get it from original sources—they have become re-sources.”

Traditional industrial models envisage a linear economy where people throw used products away. While some waste management methods are better than others, they all treat the discarded product as finished with, not just by its owner, but by society at large. That’s true even in a society that manages to recycle some of what’s thrown away.

“Where is ‘away’? What is ‘away’?” asks McDonough. “The planet, after we saw it from outer space, is clearly our home. There is no ‘away’ anymore.” So “we do not design for simplistic sourcing and disposing of undefined materials – cradle-to-grave systems. Instead, we design for end-of-use with positively defined materials seen as biological or technical nutrients in the regenerative biosphere and the circular technosphere. Now you’re in the circular economy.”

Consuming gives way to repurposing

After decades of work, McDonough says he’s “excited” to see their concept being adopted by industry, and to see the circular economy feature so strongly in EU policymaking. “These ideas, when we first put them out, were considered very radical,” he says. “It’s now obvious, which is the fun part.”

One of the earliest full-scale circular economy examples McDonough saw was in the carpet industry, where a marriage of chemistry and smart design created carpet tiles with materials that could be repurposed again and again. A major global commercial carpet company designed the first Cradle to Cradle Certified™ carpet tile with a thermoplastic backing and Nylon-6 fibres on the face.

The new carpet was no more expensive to make, and the whole tile was easily recyclable—a shredder can separate the lightweight nylon fibres from the heavier backing, both of which can be reused to make new carpets. The Nylon-6 can also be recycled back into caprolactam, an organic compound that’s used to make fibres and plastics.

But while many products contain recyclable materials, the carpet tile can be classified as “circular” because the whole product is designed to be reused in the company and the industry. Rather than being sent to a general recycling plant, the used product can go to a company that has built its production around that very material and its reusability.

“Let’s say it’s in your apartment or office,” says McDonough. The company’s phone number is on the back of each carpet tile, so when it’s time for a new carpet, “you can take the square and call this phone number and they’ll arrange for it to be picked up.” From the firm’s point of view, “you’re storing the raw materials of your company on the floors of your customers!”

Circularity doesn’t end with carpets: entire buildings can be circular too. “We use a concept called ‘buildings as material banks,’ where we design for disassembly,” explains McDonough. “When you take it down in 25 years, we know all the materials, we know where they are—digital technologies, such as blockchain, allow us to track materials across time.” The building is more dismantled than demolished, and its components and materials can be sold as commodities, rather than disposed of at a cost, as waste materials.

McDonough recently designed a Cradle to Cradle-inspired building for UEAN, a university in Bogotá, Colombia, that teaches Cradle to Cradle and circular economy design to more than 18,000 students. The building is clad in a steel frame with green, yellow and black triangles that act like leaves on a tree and help regulate the building’s temperature. Meanwhile, thermal chimneys which pull fresh air through the building, taking advantage of Bogotá’s ideal temperate climate. Hotter or colder environments require different methods and building techniques. “All sustainability is local, just like politics,” McDonough says.

Can carbon be part of the circular economy?

Re-using materials to reduce energy use is one thing. But a significant amount of energy is still coming from carbon-emitting fossil fuels. Can that carbon be circulated too, preferably in ways that don’t involve releasing it into the atmosphere later?

While nature-based solutions to carbon recovery are ideal and generally understood to be richly beneficial, point-source and direct air capture (DAC) of carbon are also going to be required to meet our global climate goals. The economics of carbon capture remain to be optimized based on policies, incentives and technologies designed to give value to the removal of carbon from the atmosphere.

Also, there is the question of what to do with carbon once we remove it. Sequestration is an option but reutilization is important—not least because profitable reuses make carbon capture more economical. Captured carbon can be used to make other chemicals, like ethanol or even jet fuel. McDonough says that while that’s preferable to leaving it in the atmosphere, “it might well end up in the atmosphere next time round.”

But in the future, McDonough says industry could put the carbon into more durable products, such as plastics. But that still requires a carbon-free, high-temperature energy source that doesn’t defeat the object of carbon capture by producing further emissions. It requires large-scale distribution of renewable electricity but also hydrogen – either blue hydrogen where carbon is sequestered or green hydrogen made with renewable energy and water.

For a while, some solutions may need to be lower-carbon rather than zero-carbon, allowing zero-carbon methods to follow in their wake. For example, McDonough points to an initiative by BASF and SABIC to power a steam cracker using renewable electricity. While the cracker itself will be used to turn fossil hydrocarbons into petrochemicals. “One can say that all these things are part of an ‘essay of clues’ that are part of our transition to a positive future,” he says.