This project has been recognised as a commendation of the 2025 Responsible Care Awards.

Despite the current market challenges, LyondellBasell and Cabot Corporation, together with other companies and organisations, are taking action to reduce natural gas consumption and lower CO₂ and nitrogen emissions in The Netherlands. The Botlek Steam Network in Rotterdam is a landmark example of how industrial collaboration can turn residual energy into a shared sustainability success. By recovering and reusing steam from production processes, the initiative significantly reduces natural gas use and greenhouse gas emissions, avoiding an estimated 100,000 tons of CO₂ per year across participating companies.

The project shows how innovation, far-reaching collaboration, and circular economy strategies can create meaningful progress toward climate goals and make industry more sustainable.

Industrial collaboration for a circular energy system

Located in the Botlek industrial area of the Netherlands, the project brings together LyondellBasell, Cabot, AVR, NetVerder, Air Liquide, LANXESS, and Huntsman, with strong support from the Port of Rotterdam, the Rotterdam municipality, and the Province of South Holland.

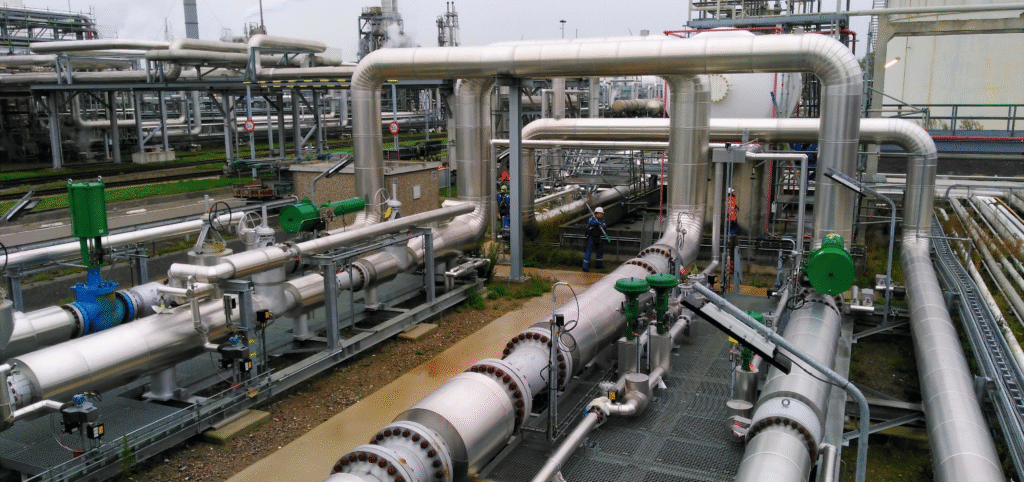

The initiative builds on existing infrastructure to expand a steam pipeline network that connects energy producers and consumers across the industrial cluster in the Rotterdam area. Steam generated from Cabot’s carbon black production process, which would otherwise be wasted, is now recovered and delivered as a valuable energy source to neighbouring facilities, primarily LyondellBasell’s Botlek site.

Key environmental benefits

By replacing natural gas-fired steam generation with recovered steam, the project enables a reduction of at least 50 million cubic meters of natural gas annually.

This translates to:

About 100,000 tons of avoided CO₂ emissions per year, with potential to reach up to 400,000 tons of avoided CO₂ emissions per year as capacity grows

Significant water savings, with Cabot’s water withdrawal reduced by more than 50 % through condensate return and reduce use of water-cooled condensers

Lower NOₓ emissions and improved overall energy efficiency across the industrial cluster

The project turns flue gas with caloric value into a shared energy source, contributing directly to the EU Green Deal and Dutch decarbonisation goals.

Collaboration and co-benefits

Botlek Steam Network demonstrates how cross-sector collaboration can take climate action at scale while supporting regional economic resilience and industrial competitiveness. Participating companies benefit from lower energy costs, reduced emissions, and enhanced sustainability performance.

A model for sustainable industry

By transforming residual heat into a shared recovered energy resource, the Botlek Steam Project sets a precedent for circular energy use in industrial clusters. It exemplifies how responsible innovation and collaboration can decarbonize energy-intensive sectors while advancing efficiency and resource conservation.