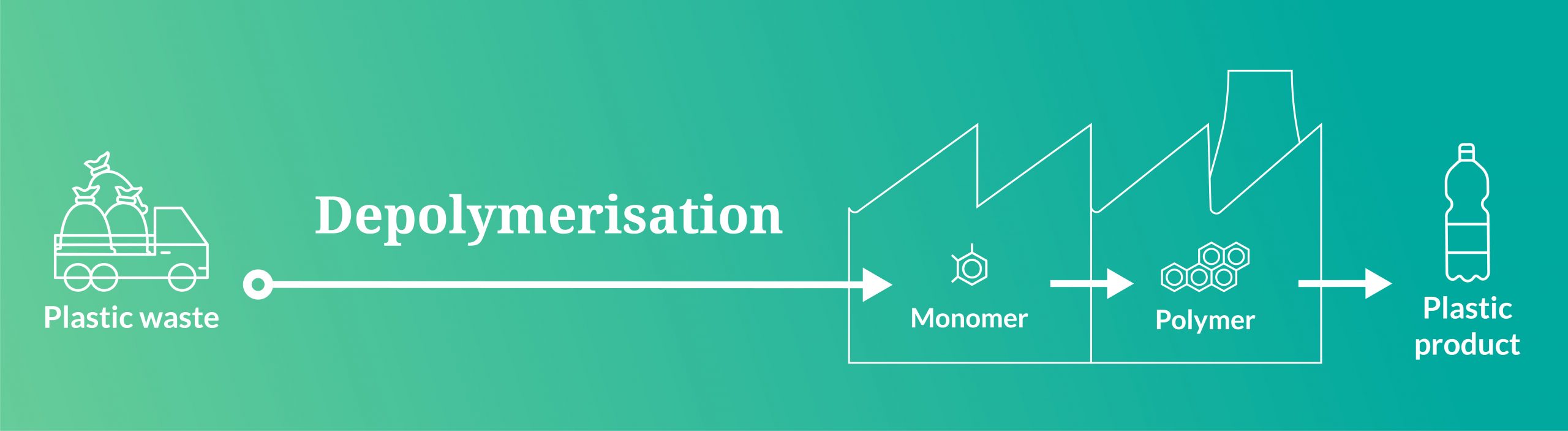

Depolymerisation: breaking it down to basic building blocks

‘Depolymerisation’ is one of the ways to chemically recycle plastic waste. In this process, sorted plastic waste is broken down into monomers (basic building blocks) to feed them back into the plastic production.

How does it work?

The depolymerisation recycling process starts with an initial step where plastic waste is sorted and prepared for further processing. The depolymerisation process – often referred to as chemolysis or solvolysis – uses different combinations of chemistry, solvents and heat to break down polymers into monomers. Monomers are the building blocks of polymers. In the following step, potential contaminants are isolated from the monomers to remove them. The monomers are then fed back into the normal plastic production processes as a secondary raw material. The plastics produced this way are of similar quality than those made from traditional fossil resources.