Shell to use one million metric tons of plastic waste per year as feedstock in its global chemical plants by 2025

In 2019, Shell announced an ambition to use one million tons of plastic waste per year as feedstock in its global chemical plants by 2025. This plan is progressing through investment, innovation and collaboration across the plastic waste value chain, helping drive the long-term growth of the industry.

A global approach

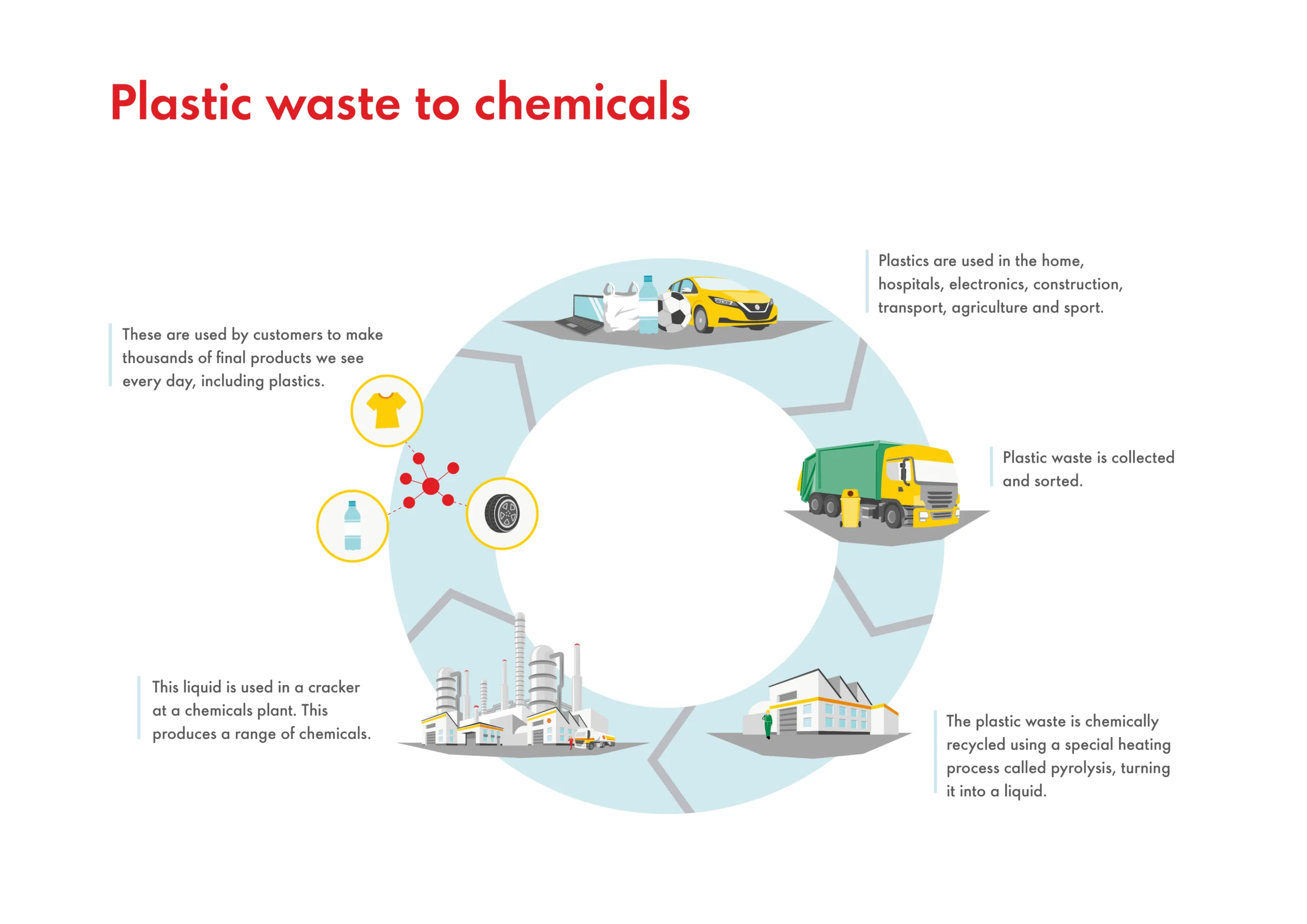

Shell’s ambition started in the U.S in 2019, with the production of high-end chemicals at Shell’s Norco plant in Louisiana, using feedstock derived from chemically recycled plastic waste, obtained via pyrolysis .

In 2021, Shell invested in BlueAlp and are working together to develop, scale-up, and deploy BlueAlp’s plastic waste to chemicals feedstock technology in Europe. In the Netherlands, the company intends to build two conversion units with the combined capacity to process approximately 30,000 tons of tough-to-recycle plastic waste. The two units are expected to be operational in 2023, using 100 percent of the pyrolysis oil at its plants in the Netherlands and Germany.

In Asia, Shell and Environmental Solutions Asia (ESA) signed an exclusive pyrolysis oil supply agreement for 12KT per annum. This deal illustrates the ongoing expansion of the pyrolysis oil market in Asia; and complements existing pyrolysis oil agreements with partners in the U.S and Europe.

Building solutions

Shell is investing in technology to give difficult-to-recycle plastic a new lease on life and turn it into something useful. However, processing a broad range of plastic waste products using pyrolysis technology can produce an inconsistent purity in the pyrolysis oil due to contaminants, limiting useable quantities. Shell is tackling this industry-wide problem with its proprietary upgrader technology that can use pyrolysis oil with a wider range of characteristics and reduce the need for low-grade pyrolysis oil to be re-processed.

Circularity means addressing the whole plastic-waste-to-chemicals value chain, where collection and sorting of waste is increasingly becoming an area of opportunity. In Singapore, Wah & Hua, ESA and Shell signed collaboration agreements to work together on the collection, sorting and supply of plastic waste that will be used in Shell’s Singapore facilities. Collaboration is vital to advance chemical recycling as a complimentary measure to reduce and reuse measures. Governments can play a key role in designing the correct regulatory environment, while promoting greater corporate and social accountability across the plastics value chain, to help achieve a stronger circular economy.