A circular economy for styrenics

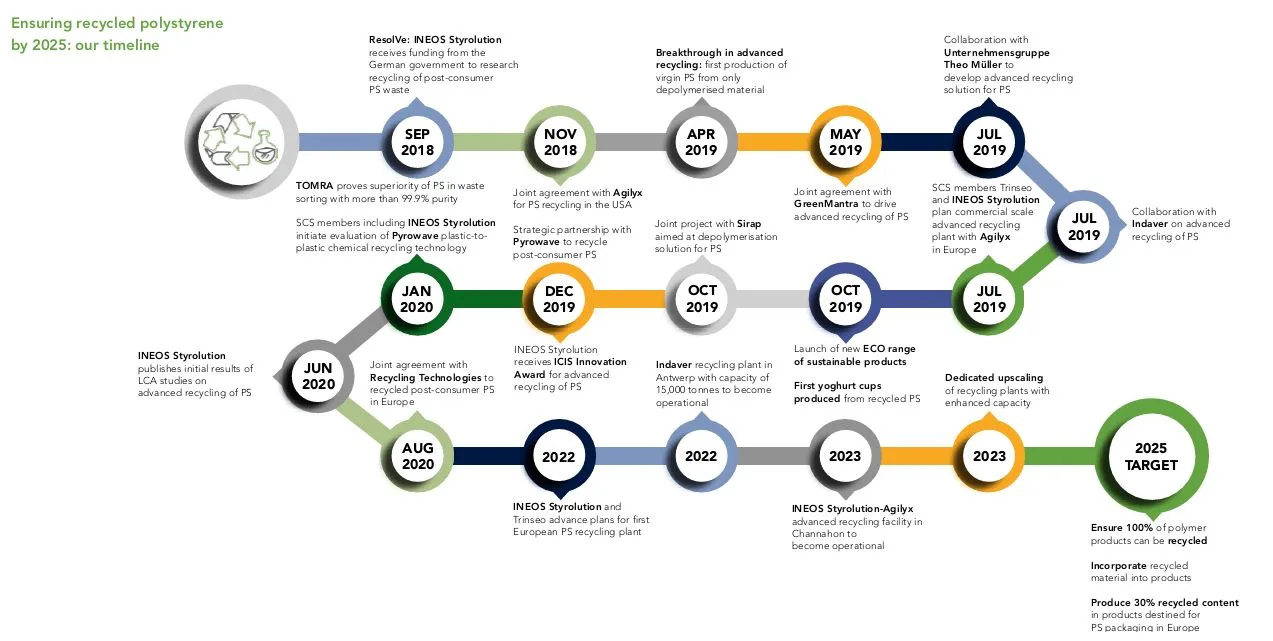

Styrenics are specialty plastic solutions used for applications in a wide range of industries, including automotive, electronics, household, healthcare, construction and packaging. INEOS Styrolution is dedicated to a circular economy for styrenics and is working towards offering recycled polystyrene, a polymer made from the monomer styrene, to its customers by 2025.

Recycling polystyrene through depolymerisation – follow the journey of a yoghurt cup. Watch INEOS video.

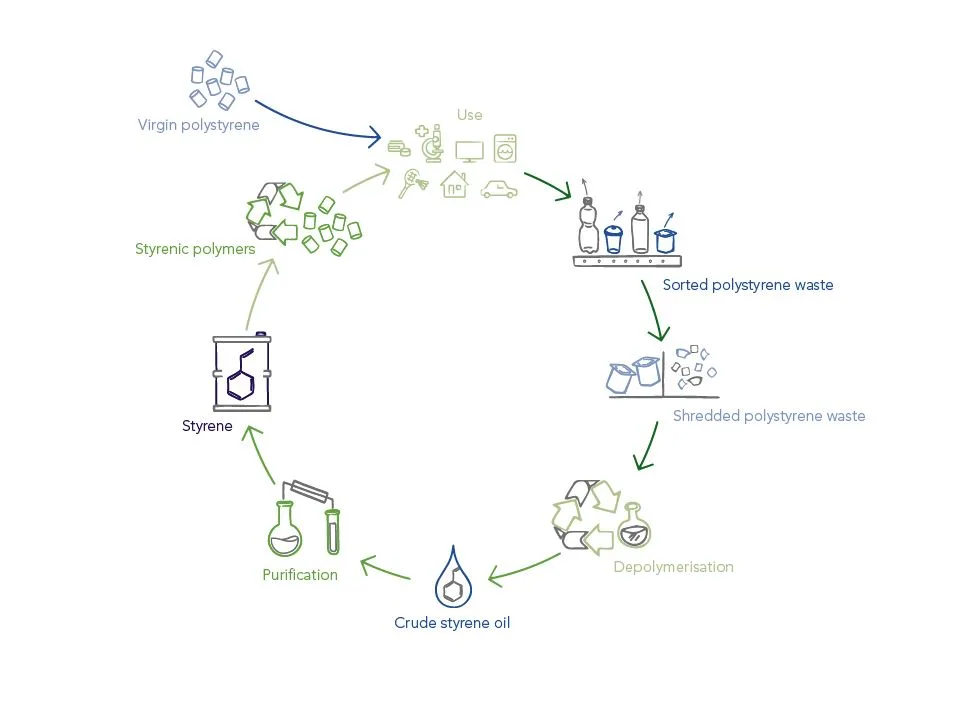

INEOS Styrolution is now focusing on the commercialisation of its depolymerisation technology. Depolymerisation is a technology made possible by the intrinsic properties of polystyrene, which allows the polymer to be returned to its building blocks, styrene monomer. To this end, the company is cooperating with leading global technology providers by building recycling plants in North America and Europe to convert post-consumer polystyrene waste back into feedstock. These projects follow the extensive research and development (R&D) efforts that INEOS Styrolution has already undertaken into the depolymerisation technology.

One of the breakthrough achievements was the first successful test run on lab-scale producing virgin polystyrene from previously depolymerised material. Another was the finding that polystyrene is in fact made for recycling, allowing for a broad range of recycling options.

Depolymerisation of polystyrene – how it works!

The ResolVe project – Chemical recycling of polystyrene

ResolVe is a research project focused on the chemical recycling of polystyrene.

Funded by the German Federal Ministry of Education and Research, its goal is to explore the recycling of polystyrene. The project analysed various aspects of recycling polystyrene, including the logistical and environmental aspects of the recycling concept. Results show that depolymerisation is a valid recycling concept for polystyrene, which not only helps to reduce waste ending up in landfill and convert waste into valuable feedstock, but also that it helps to reduce CO2 production and save fossil feedstock.

A breakthrough achievement related to the ResolVe project was the first successful test run producing virgin polystyrene from previously depolymerised polystyrene waste (April 2019).

Ensuring recycling polystyren by 2050: our timeline

Partnerships to accelerate advanced recycling:

INEOS Olefins & Polymers Europe and Plastic Energy, have announced a Memorandum of Understanding to produce 100,000 tonnes per annum of recycled raw materials from plastic waste. These new raw materials will enable a circular approach to produce essential plastic items that meet the requirements of demanding food contact and medical applications. Production will be based in Köln, Germany.

INEOS Styrolution and Indaver, have signed an offtake agreement for recycled styrene monomer from Indaver’s planned depolymerisation plant in Antwerp, Belgium. This agreement closes the loop towards a circular economy for polystyrene. It will enable INEOS to produce polystyrene from recycled feedstock replacing styrene monomer produced from fossil feedstock. The polystyrene from recycled feedstock will have identical properties as the virgin material with a lower CO2 footprint.