Removal of impurities in pyrolysis oil to allow its use for new polymer production

The world is facing various environmental issues. There is no alternative to reducing our consumption, reusing what we have and recycling our waste. Plastic waste should be recycled by mechanical recycling as much as possible, but there is still a significant amount of plastic waste that requires a different recycling method. The pyrolysis process offers a good complementary solution for treating the remaining plastic waste.

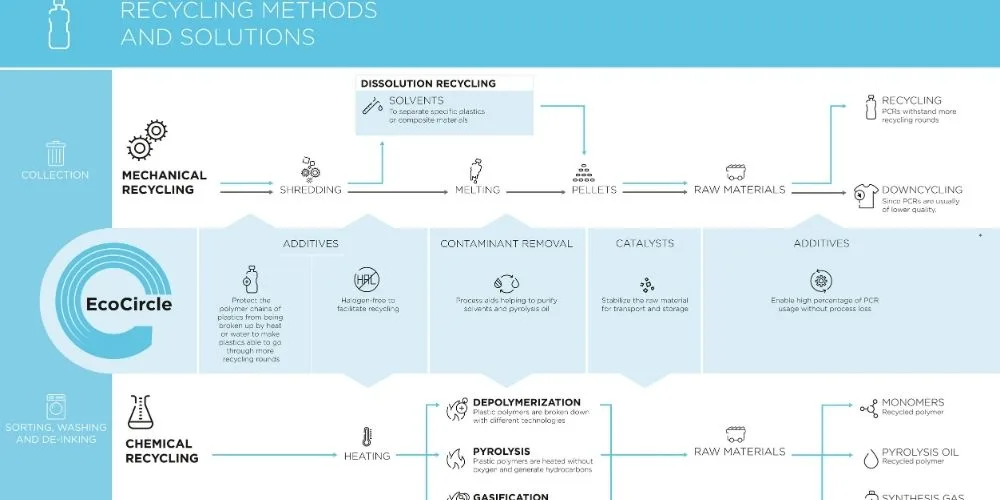

Video caption: Chemical recycling offers a good complementary recycling solution to mechanical recycling and Clariant products can help make it efficient.

The output of the process is pyrolysis oils that are often intended to be used as cracker feedstock. Due to the nature of the plastic waste used as feedstock in the thermochemical process, pyrolysis oils often contain high amounts of contaminants. Significant amounts of metals, chlorides, sulphur or other contaminants in pyrolysis oils reduce their use as cracker feedstock.

Clariant has developed different products/solutions to remove these contaminants and stabilise the resulting pyrolysis oil, for example for transport. By applying these solutions, the pyrolysis oil can be enhanced to make it fit for purpose.

Clariant’s experts establish the right solution based on the specific situation of the customer process. This solution is part of the company’s EcoCircle Initiative, enabling the industry to transition towards a circular plastic value chain.