The sustainable operation of the chemical industry relies on its workforce. Amid labour shortages, attracting talent for specialised and technical roles is crucial for both short-term functionality and long-term success. Safety is a critical factor for protecting the health of both employees and consumers, and the industry continuously strives to prevent accidents through a strong safety culture. When designing for sustainability, the industry focuses on safety for employees and the environment during production, on safety of the production process itself, and on chemical safety of products. The chemical industry addresses the social targets of the UN-SDGs by improving safety, thereby supporting decent work (SDG 8) and good health (SDG 3).

Contribution to the EU Green Deal

The EU Green Deal prioritises improving the well-being and health of citizens and future generations. The chemical industry plays an important role in achieving these goals by driving innovation and sustainability, creating employment opportunities, and contributing to economic growth. By investing in future-proof jobs and skills training, the industry ensures its workforce is adaptable and skilled for the transition to a circular and digital economy. Additionally, the industry maintains stringent operational safety standards to protect workers and the environment, ensuring the overall well-being of employees and surrounding communities.

Employment

The workforce in the chemical industry is vital for its sustainable operation in both the short and long term. In times of labor shortages, attracting necessary talent for specialized and technical vacancies in the chemical sector becomes imperative.

With slightly over 1 million employees, the chemical industry accounts for approximately 0.35% of all employees in the EU economy.

Operational Safety

Safety is the key factor for the chemical industry to protect and maintain the health of both employees and consumers. The chemical industry strives continuously to prevent accidents by embedding a strong safety culture.

Accidents at work

The chemical industry aims to continuously improve safety conditions in its manufacturing sites for its employees, contractors and visitors who are active in the sector. As a result, the number of non-fatal accidents at work decreased between 2010 and 2014 by almost 25%. The situation plateaued between 2014-2018. While the incidence rate remains very low, the sector continues working on improving safety among its workforce and prevention of accidents remains at the top of its priorities.

In 2021, the incidence rate of non-fatal accidents at work has decreased by 28% since 2010, while the incidence rate of fatal accidents at work has decreased by 53% since 2010. While the incidence rate remains very low, the sector continues working on improving safety among its workforce and prevention of accidents remains at the top of its priorities.

Use Best available Techniques to minimise emissions to water and air and to retrofit chemical plants

Use Best available Techniques to minimise emissions to water and air and to retrofit chemical plantsThe chemical industry invests continuously in the improvement of their production processes. Best available techniques are implemented to optimise production and to minimise emissions to the environment.

Emission of air pollutants

Since 2007, the chemical industry has significantly reduced acidifying emissions into the air, with ammonia, nitrogen oxide, and sulfur oxide emissions declining by 58%, 54%, and 79%, respectively. The implementation of measures to reduce these emissions was further triggered by Directive 2010/75/EU on industrial emissions, adopted by Member States in January 2013.

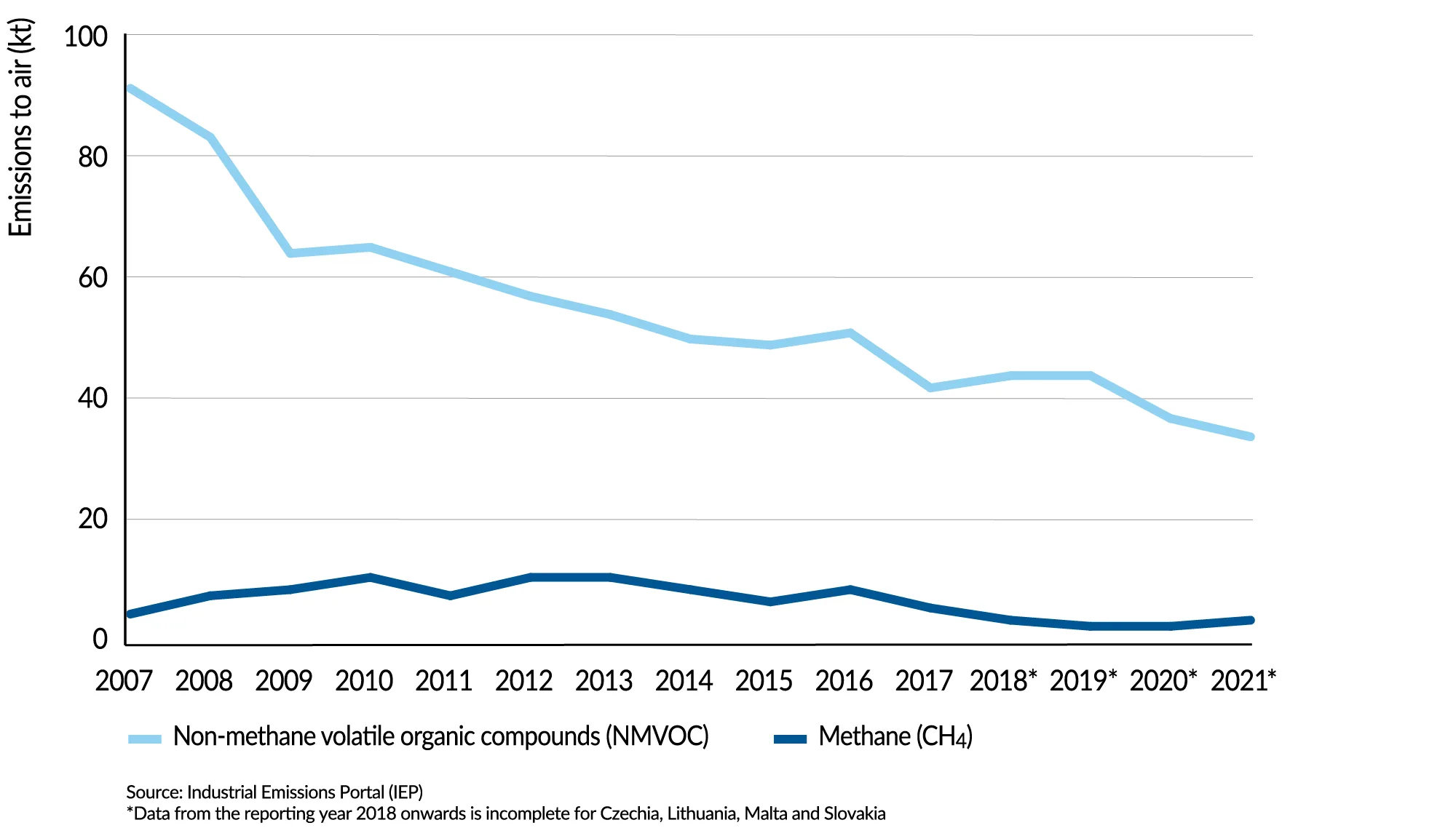

Methane & NMVOC emissions to air

The chemical sector has achieved a 62% reduction in non-methane volatile organic compounds (NMVOC) since 2007 through various measures like process optimization and enhanced emissions control during storage and transport. Additionally, a declining trend in methane emissions has been observed since 2013.

Emission of water pollutants

The Chemical Oxygen Demand (COD) decreased significantly until 2012, but increased slightly again until 2019. Revisions of the Common Wastewater BREF were done in 2003 and 2016 to which companies had to comply with by 2007 and 2020.

Maximise process safety: avoiding accidental release of chemicals

The chemical industry strives to maximise its process safety to avoid the accidental release of chemicals to the environment. Accidental release might impact human health as well as environmental status but can also create unsafe working conditions. Therefore, reporting on process safety is a mandatory metric within the Responsible Care Leadership Group. A clear definition of process safety events which have to be reported is worked out, but differ from the accidental pollution releases reported in the E-PRTR database of the EEA which are used here.

Accidental pollutant releases

The number of accidental pollutant releases to water and air decreased with around 50% over the period 2007-2019. However, the number of accidental pollutant releases is still between 600 and 1000 for both water and air. The accidental pollutant releases to land did not show a decreasing trend, but the number was always under 10, except for 2007, 2008 and 2018.

Accidental pollutant releases to air, water, and soil

Sustainable supply chain management

Sustainability reports and assessments of the industry’s supply chain can be used during procurement, in the selection of new or the reevaluation of current suppliers supporting the due diligence of the chemical companies. The chemical industry has voluntary tools – Safety & Quality Assessment for Sustainability (SQAS) and Together for Sustainability (TfS)– to assess the HSE and sustainability performance of its suppliers which can be used in the selection process of these suppliers.

Suppliers in the chemical sector audited for sustainability performance

Valid SQAS and TfS assessments per year for suppliers of the European chemical industry

The number of suppliers’ sites in the chemical supply chain with valid SQAS assessments or TfS audits is on the rise. This indicates a growing opportunity for chemical companies to incorporate sustainability criteria into their procurement processes.